VIDEO: Working With Crinkle Metal Sheet

What Is Crinkle Metal Sheet?

Crinkle metal sheet, also known as crinkle bi-metal, is a great 'cheat' way of achieving a reticulated look.

It immediately reticulates with lovely crinkled texture as soon as it is brought up to temperature with a gas torch - without the need for any surface preparation. It is fully annealed which makes it soft and easy to form. It can be formed before bringing out the surface texture and it will hold its shape perfectly.

On this page, we go into detail about how crinkle metal sheet works with tips and advice on how to use it.

Specification...

- 80% silver and 20% copper reticulation alloy on a fine silver (99.99%) back.

- 96.6% overall silver content.

- The reticulation alloy is 1/6 of the thickness of the metal.

- It is fully annealed, making it easy to form.

Please note that we no longer stock crinkle metal sheet, but we have kept our advice page and video available for educational purposes. If you would like to reticulate metal sheet, we recommend watching our video tutorials with Kim in our 12 Months Of Metal series.

How To Use Crinkle Metal Sheet

1. Place the metal on a charcoal or similar heat resistant block pattern side up. The pattern will disappear on heating.

2. Bring the piece slowly up to heat with a moving flame.

3. When the metal reaches the proper temperature the surface will begin to form waves and then start to crawl as it crinkles up. A small oxidising flame works best.

4. Remove the heat, cool and pickle as usual. The piece may be re-heated if there are any areas that you do not like.

5. Overheating will cause the alloy to flow freely on the surface of the fine silver where it may be stirred with a soldering poker or metal brush for unusual effects.

Granules, chips and other heat resistant materials can be dropped into the molten surface for even more special effects.

Watch how to use crinkle metal sheet below...

Finishing...

- Solder, pickle or patina as you would with sterling silver.

- Avoid prolonged pickling.

- Fabricate with easy and medium solder and try to avoid hard.

- You may prefer to crinkle your metal before soldering as the heating required as soldering will cause the metal to crinkle. You will have more control if you keep the processes separate.

- Have fun and don’t be afraid to experiment with this interesting metal!

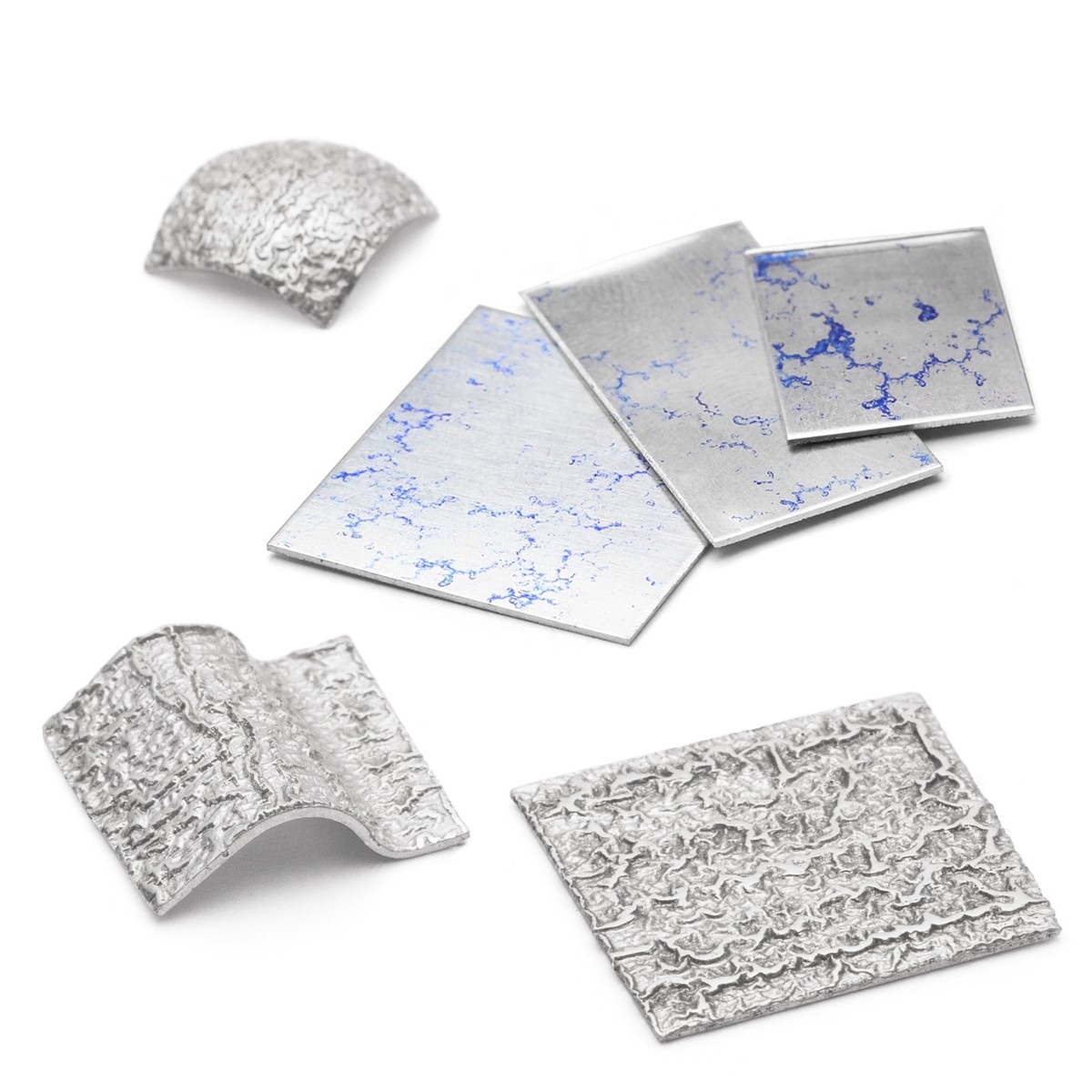

Here is an example of how the crinkle metal can look...

Reticulating From Scratch With Kim Thomson

In our 12 Months Of Metal series, Kim shares a brilliant tutorial on how to reticulate silver, talking you through every step and all the tools you need to achieve this technique. Kim also shows you an example of reticulated copper!

Watch more videos and tutorials on reticulation with Kim Thomson over on our blog.

Also in this section:

- Guide To Sanding & Polishing For Jewellery Making

- Hand Polishing Your Jewellery With Polishing Papers

- A Guide To Texturing Metals For Jewellery Making

- Top Tools For Making Textures On Metal

- Beginner's Guide To Chasing & Repoussé

- How To Make Easy Textured Earrings

- How To Make A Hammered Copper & Silver Heart Pendant

- How To Make A Textured Cuff Bracelet

- How To Make A Metal Leaf Decoration

- How To Use Doming Block & Punches For Jewellery Making

- How To Make Domed Metal Earrings With A Doming Block

- How To Engrave Your Drawings On Art Clay Copper

- Textured Washer Bracelet Tutorial With Guest Jeweller Laura Grey

- Barrelling Machine For Polishing Metal - Everything You Need To Know

- Tumbling Machine For Polishing Stones and Glass- Everything You Need To Know

- Polishing Jewellery Q&A With Stephen M Goldsmith

- Town Talk Products For Cleaning & Caring For Jewellery

- Creating A Resin Bird Pendant With Designer Sarah Hoare

- VIDEO: How To Create Patina With Liver Of Sulphur

- 2 Ways To Apply Liver Of Sulphur

- VIDEO: How To Use Silver Plating Solution

- How To Clean & Prevent Tarnished Jewellery

- Why You Need Anti Tarnish Paper Strips

- How To Use Midas Finish Seal Lacquer

- How To Use Renaissance Wax To Prevent Tarnished Jewellery

- VIDEO: Working With Crinkle Metal Sheet

- A Guide To Using Mokume Gane Metal For Jewellery Making

HAVE A QUESTION?

If you have any questions, feel free to get in touch with our friendly team who will be more than happy to give you advice over email or on the phone.

You can learn more and find inspiration by visiting our Jewellery Making Tutorials, Jewellery Making Kits and YouTube Channel. Don't forget to follow us on social media and tag us in your designs on Instagram & Facebook, we would love to see!