Soldering Flux For Jewellery Making Explained

What Is Flux & Why Is It Important?

Flux is a compound which is applied onto a joint before soldering to prevent oxides. Using flux keeps your piece clean, allowing the solder to flow easily once brought up to temperature. Below, we share with you the many types of flux available.

Soldering For Jewellers by Rebecca Skeels: "Flux dissolves oxide residues and stops further oxides from forming, which means it keeps the metal clean and allows the solder to work. If an oxide layer is formed, the solder will only adhere to the surface like glue and is likely to come apart later... Flux also contains a wetting agent that encourages solder to flow along the seams, into the joints and into the structure of metal, creating a strong bond."

The Traditional Form Of Flux With A Borax Cone

What Is A Borax Cone?

A borax cone is a traditional and cost effective flux which can be used with all solders. It is used to make a paste when mixed with water, which can then be applied to the solder joint.

How Do I Use A Borax Cone?

You will need an unglazed ceramic dish (we offer a borax dish which is specifically designed for this), begin by pouring water into the dish and tipping away any excess, a small amount of water will be enough to form the paste. Start grinding down the cone against the dish in a circular motion. You will see a paste begin to form which is the soldering flux, ready to apply to your joint using a flux brush before soldering. The remaining flux left in the dish can be used again using a little bit of water.

Andrew Berry from At The Bench, shows you how to use your borax cone and dish below...

Explore More Flux Options...

Although the borax cone is considered a traditional form of flux and is a popular choice among jewellers, there are also other options available.

Argotect Flux

Argotect flux can be used with all of our types of solder. This needs to be mixed with water to create a smooth paste and applied to the clean solder joint using a flux brush.

Tenacity Flux

Tenacity flux can be used for soldering at medium temperatures of 600 - 900ºc, great for using with medium and hard solder. It works the same as the borax cone, so needs to be mixed with water to create a smooth paste. This can then be applied to the solder joint. After soldering, you may find that the flux has left residue which is hard to remove - you may need to file the area.

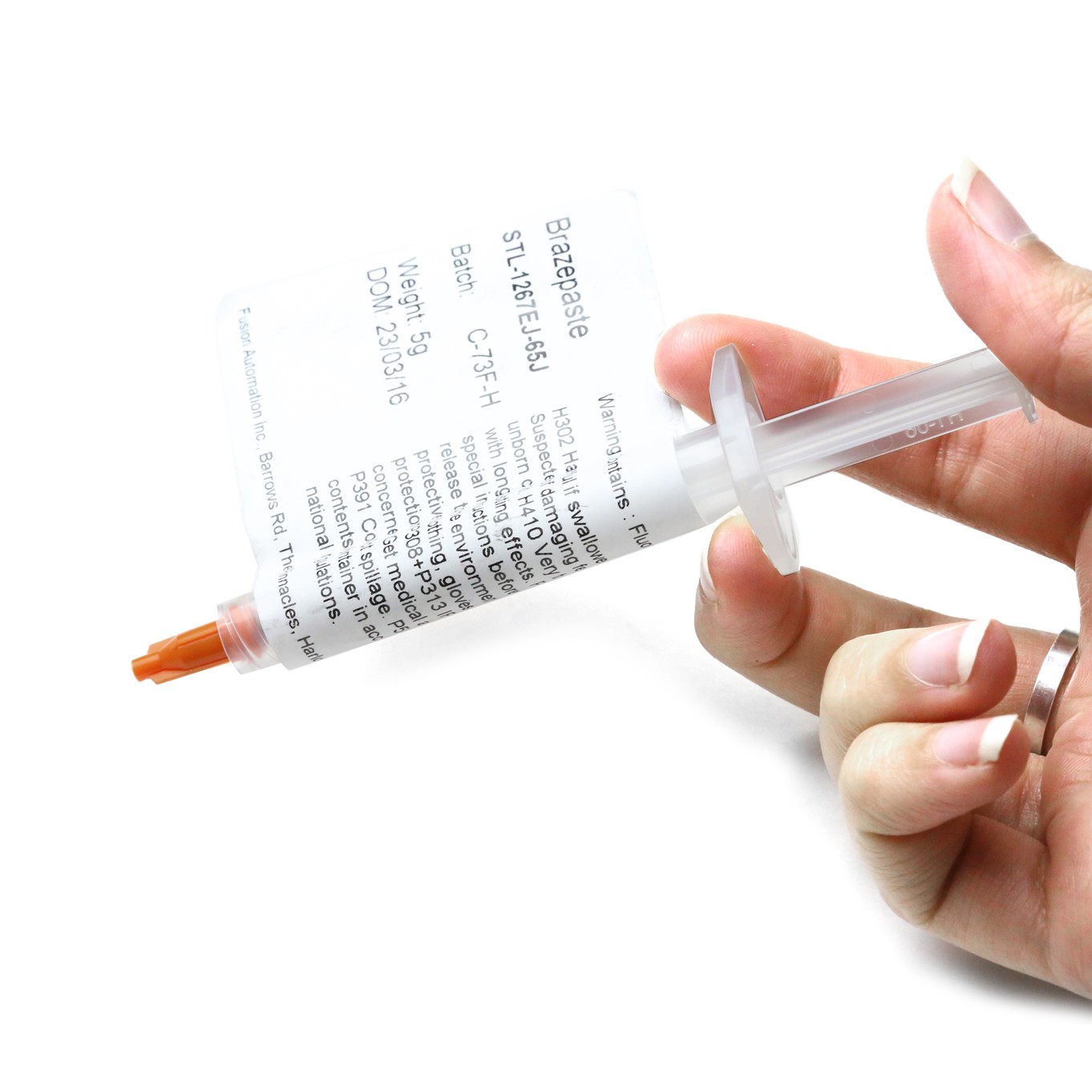

Solder Paste

Solder paste is modern and one of our best selling products for soldering. It is great to use for single soldering jobs, it's very simple and quick to use - saving you valuable time at the bench. The paste doesn't need any extra flux as it is already mixed into the paste.

Our Recommended Soldering Books...

Read more in depth information on soldering in these brilliant book available on our website. Browse our full range of jewellery making books here.

Soldering For Jewellers by Rebecca Skeels

This book is a great resource for anyone wishing to start jewellery making or would like to extend their knowledge. It runs through the basics of soldering, covering the preparation, planning and basic techniques. Read our review here.

The Art Of Soldering For Jewellery Makers by Wing Mun Devenney

This is a comprehensive book, guides you through the fundamentals of soldering from understanding solder to fixing mistakes. You'll find 15 projects with clear concise step-by-step instructions and fabulous photography too.