How To Prevent & Remove Fire Scale & Fire Stain

You’ve finished your beautiful piece of jewellery and suddenly spot a dark shadow on your design! It’s every jeweller’s worst nightmare, especially when they’re in a hurry.

This dark purplish colouring is fire stain and is caused by oxidisation, effecting metal alloys containing copper such as sterling silver - but don’t worry, it can be fixed! Did you know that sterling silver alloy is made up of 92.5% pure silver and 7.5% copper or other metals?

In this post, we share with you the difference between fire scale and fire stain, as well as how to prevent and remove it from your handmade jewellery.

The Difference Between Fire Scale & Fire Stain

What is fire scale?

Fire scale naturally develops during the soldering process, where oxygen in the air comes into contact with the surface of metal, oxidising the copper content within the metal and bringing copper oxide to the surface. This usually appears as a grey or dark black colour.

The photos show an example from Kim's 12 Months Of Metal series showing you before and after of pickling your piece.

How do you get rid of fire scale?

Safety pickle is a workshop essential for removing oxides caused by heat during soldering. Simply mix 1 teaspoon of the powder with warm water and immerse your pieces in the solution once you have soldered and leave them for a few hours or overnight. Your pieces should then be clean and ready to work on. Don’t forget to always use plastic tweezers when inserting or removing items from the pickle bath, as if you use metal tweezers it can create a chemical reaction which can copper plate your pieces.

What is fire stain?

Fire stain doesn’t usually become apparent until the final stages of polishing your jewellery – which is frustrating when you think you’re coming to the end!

You will notice that the metal has blotches of pink, purple or dark marks. Unfortunately, unlike fire scale, fire stain cannot be removed by pickling the piece again.

Photo from Gemiprecious Jewellery Designs shows an example of fire stain on sterling silver, however it's important to note that fire stain can be very subtle with an almost imperceptible shadow.

A good tip to remember once you have finished your piece is to place it on top of a white piece of paper, this will make it clear if there is any fire stain.

How do I get rid of fire stain?

The most common and easiest way to remove fire stain is by using an abrasion to file away the fire scale and to then re-polish your piece.

Take a look at a few products we supply below including wet and dry sanding sheets, tripoli and radial discs.

Top Products For Removing Fire Stain

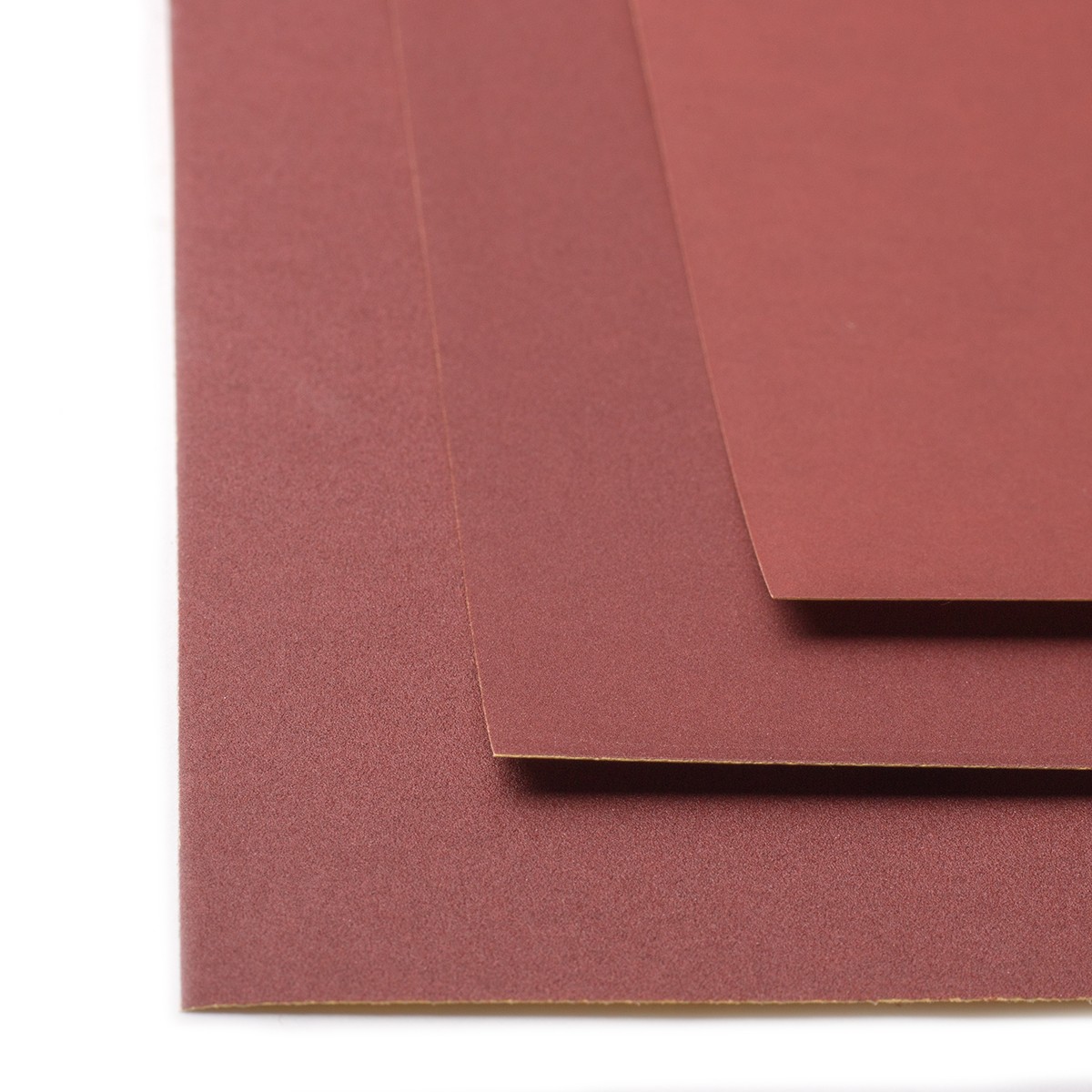

Wet & dry sanding sheets

These wet and dry sanding sheets come in a range of grades, 1200 grit (fine), 600 grit (medium) and 400 grit (coarse).

Work up through the grades from coarse to fine to remove any unwanted fire stain, scratches or file marks to prepare your work for re-polishing.

Tripoli

Tripoli is recommended for removing fire stain, containing miniscule abrasive particles which will help remove fine scratches too. We recommend using Tripoli after the wet and dry sanding sheets to remove any deep marks and then Tripoli to prepare your surface. At Kernowcraft, we supply large swansdown mops to use on a bench polisher or alternatively small, soft polishing mops which can be used with the Dremel Multi Tool.

Radial discs

These Scotch-Brite radial bristle discs have a graded 3M ceramic abrasive grain technology, making them a great choice for removing fire stain. They provide polishing, cleaning and finishing without any need for chemicals or compounds. They are quick and easy to use with your rotary tool (such as the Dremel Multi Tool) and are really flexible, so they can reach any awkward areas of your work.

How do I prevent fire scale and fire stain?

Use the correct sized flame

It’s important that you choose the correct sized flame for your piece as you can easily overheat your piece and with a smaller flame, it can take longer to melt the solder.

Ensure your piece is clean

If your piece of jewellery is dirty (with oil from your fingers for example), it will make the soldering process longer and you are more likely to overheat your piece and cause fire stain.

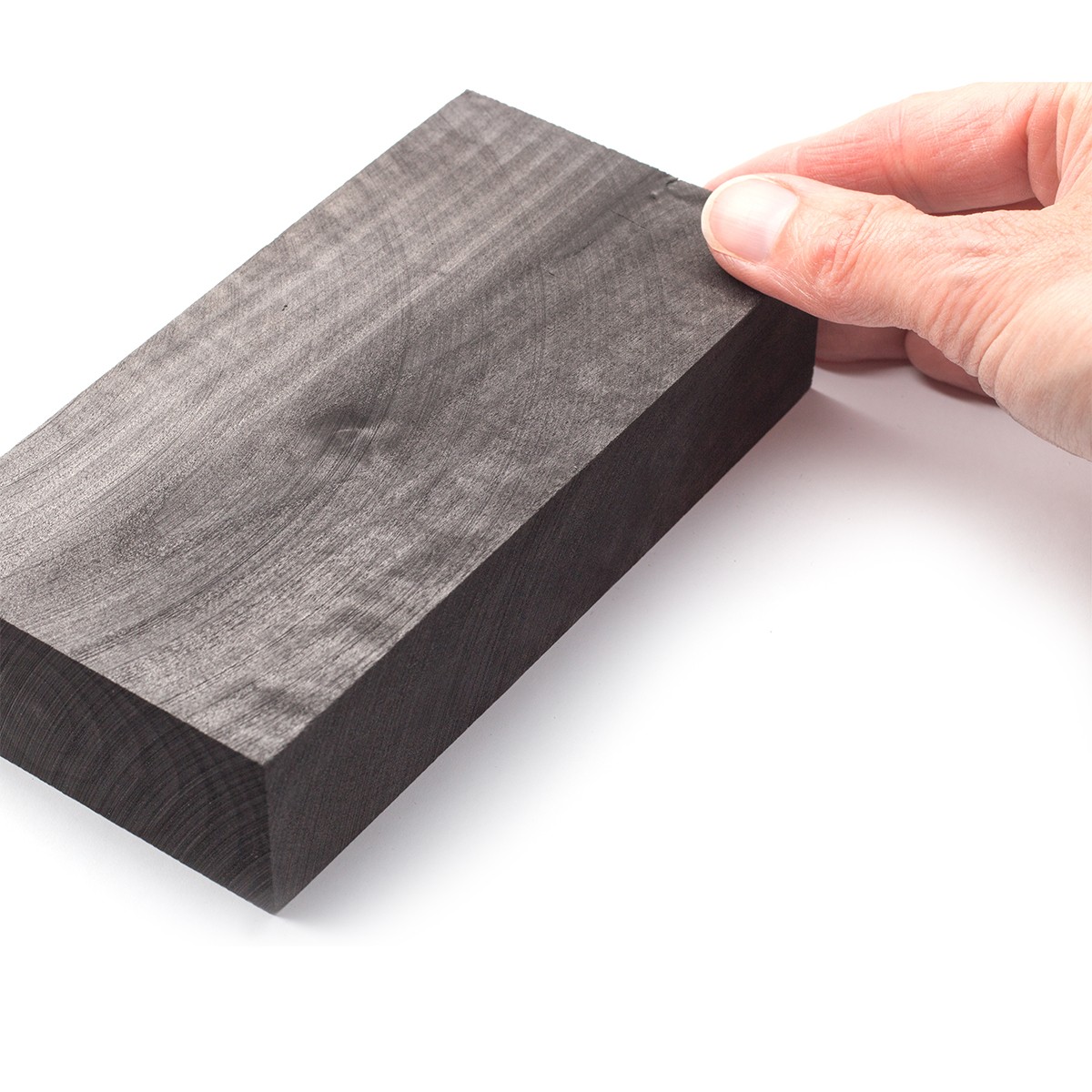

Use a charcoal block

A charcoal block is a great addition to your workshop and an excellent soldering surface as it reflects the heat back onto the metal being soldered for quicker heating.

The block also consumes the oxygen around the piece being soldered, which helps reduce fire stain.

Use argotect flux

Argotect flux can be used with all types of solder and can help prevent fire stain - especially on larger surfaces. Simply mix with water to create a smooth paste, which can then be applied to the solder joint before heating. Always ensure that you apply heat to the whole piece so that the correct temperature is achieved and maintained, until the solder melts and flows.